Industrial visit to CNC Machining center & Toolrooms.

Industrial visit to CNC Machining center & Toolrooms.

Industrial visit to CNC Machining center & Toolrooms.

Complete CAD/CAM Training Course

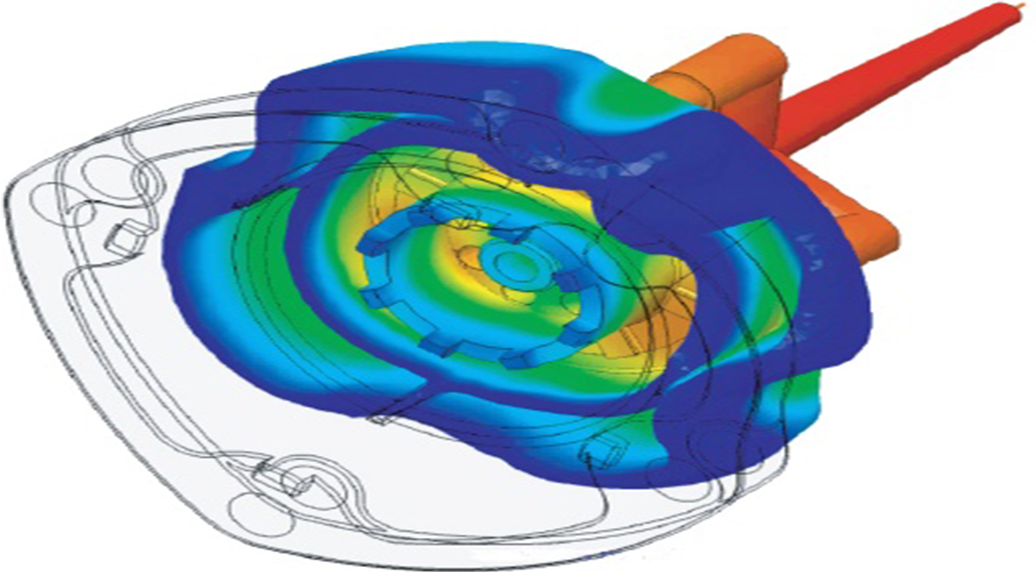

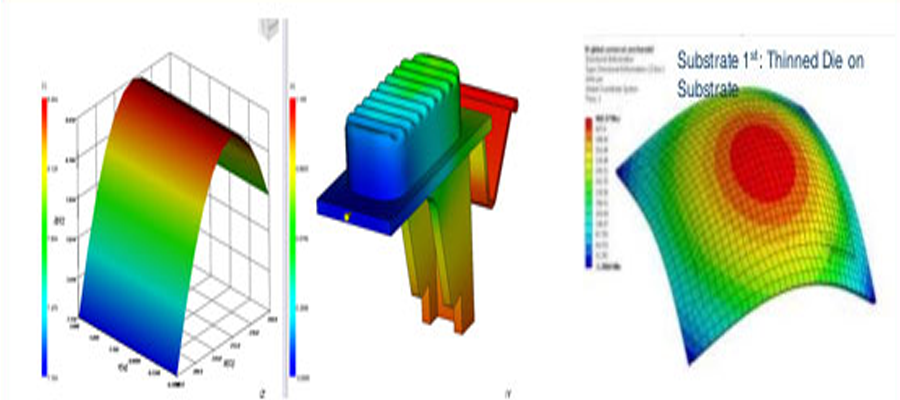

ASK me Engineers conducts CAE courses of various levels: First level is for engineers who have recently started using CAE in the Design process & the Second level, is for engineers with some experience of using CAE & who are conversant with the Product Design requirements of your organization & who have access to the software they are using for simulation.

Apply leading Mould Simulation Technology for first time right Design

Learn advance techniques and best practises to improve Mold Designs molding productivity

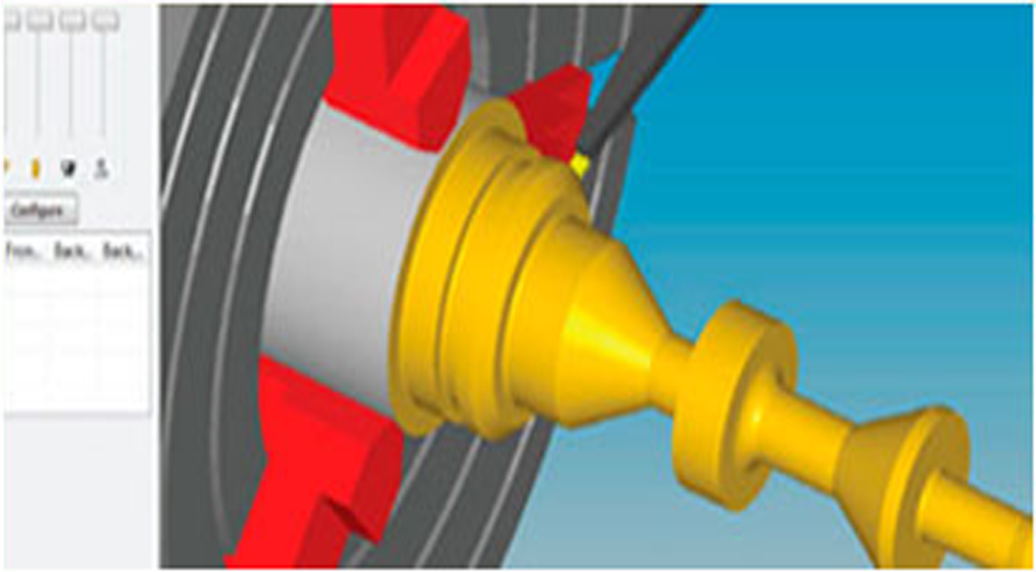

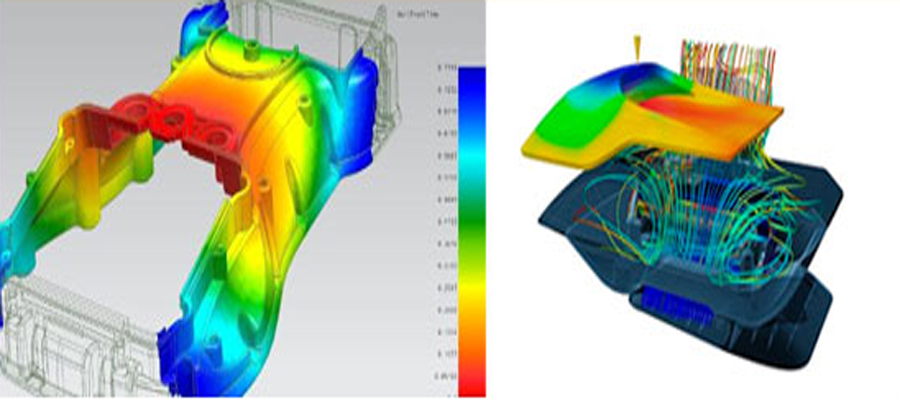

Apply leading Design & Manufacturing Technology (RPT) for advancement of Industry

Apply leading Design & Manufacturing Technology for advancement of Industry

Apply leading Design & Manufacturing Technology for advancement of Industry

Learn Latest 3D Scanning & 3D printing with Geomagic Studio & Wrap Software.

Apply leading Reverse Engineering techniques for 3D Scanning & Manufacturing i.e. 3D Printing Technology for new Product Development.

Learn to convert your Innovative design Ideas into working designs by

Creating, Visualizing & Manufacturing (RPT)